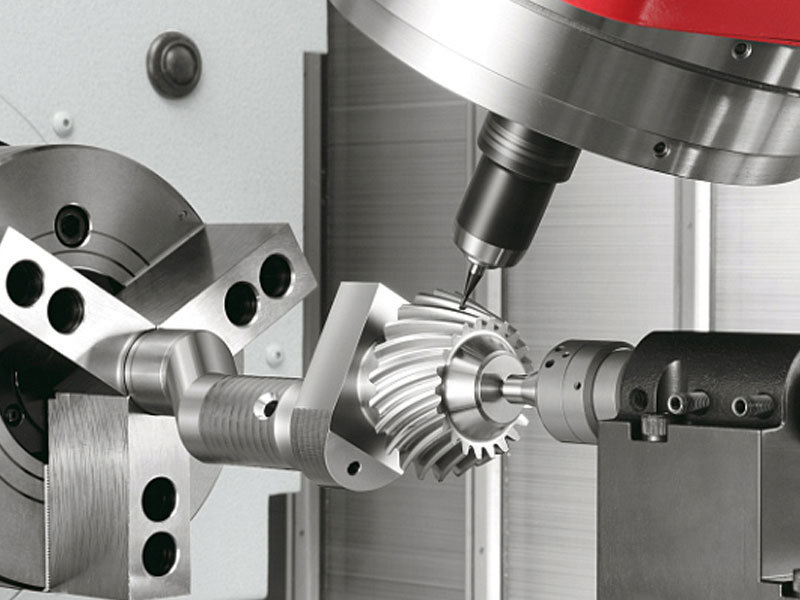

How to maintain CNC machine tools?

Aug 28,2024

Numerical control lathe is a high-precision and high-efficiency automated machine tool that can process complex workpieces such as linear cylinders, oblique cylinders, and arcs. It is necessary to carry out reasonable maintenance in order to ensure the working accuracy of the lathe and extend its service life.

The common ways to maintain and upkeep CNC machine tools include: oil lubrication, splash lubrication, oil rope guide lubrication, ball oil cup lubrication, butter cup lubrication, and oil pump oil lubrication.

The parts inside the spindle box are lubricated with oil pump circulation or splash lubrication. The lubricating oil inside the box is usually replaced once every three months. There is an oil window on the spindle body. If no oil output is found in the oil window, it indicates that there is a fault in the oil pump delivery system. The machine should be stopped immediately to check the cause of the oil shortage, and the lathe can only be started after repair.

In addition to using gear splash lubrication, the gears and bearings inside the feed box also have an oil storage tank on the feed box that is lubricated with oil ropes. Oil should be added to this oil storage tank once per shift. The intermediate gear shaft bearing of the gearbox is lubricated with grease cup, once per shift. The bed guide rail and skateboard guide rail should be wiped clean and oiled with an oil gun before and after operation.

The daily maintenance and upkeep requirements for lathes are as follows:

1、 After working every day, cut off the power and ensure that all surfaces, covers, guide rails, screws, and bars of the lathe are free of oil stains, iron filings, and the surface of the lathe is clean.

2、 Every week, it is required to maintain the cleanliness and lubrication of the bed guide surface and the sliding plate guide surface. Usually, after running the CNC lathe for 500 hours, a first level maintenance is required. The maintenance work is mainly carried out by operators with the cooperation of maintenance personnel. When performing maintenance, the power must be cut off first, and then the following sequence and requirements should be followed: First, perform maintenance on the spindle. Firstly, clean the oil filter to ensure it is free of impurities. The

3、 Adjust the clearance between the brake and clutch friction plates. Secondly, exchange the maintenance of the gearbox. Firstly, clean the gears and shaft sleeves, and inject new grease into the oil cup. Secondly, adjust the meshing clearance of the gears. Thirdly, check for any shaking of the shaft sleeve.

3、 Maintenance of skateboards and knife racks.

4、 Maintenance of the tailstock (wiping the exterior and adding oil and lubrication).

5、 Maintenance of lubrication system. Firstly, clean the cooling pump and oil filter. Secondly, ensure that the oil circuit is unobstructed. Thirdly, check the oil quality and maintain it in good condition (clear oil level)

6、 Maintenance of electrical appliances. Firstly, clean the dust and debris on the electric motor and electrical box. Secondly, the electrical devices should be fixed neatly.

7、 Maintenance of appearance. Firstly, clean the surface and casing of the CNC lathe to keep its interior and exterior clean, free from rust and oil stains. Secondly, check and replenish all screws and handles. After cleaning and wiping, all components should be lubricated as necessary.

NEXT:

Contact Us

E-mail :

fanminga@qijijixie.com

Phone/WhatsApp:

+8613703194661,+8618732920203

Address:

Fuyang High tech Economic Development Zone, Xingtai City, Hebei Province, China.