How to improve the machining accuracy of CNC lathes?

Aug 28,2024

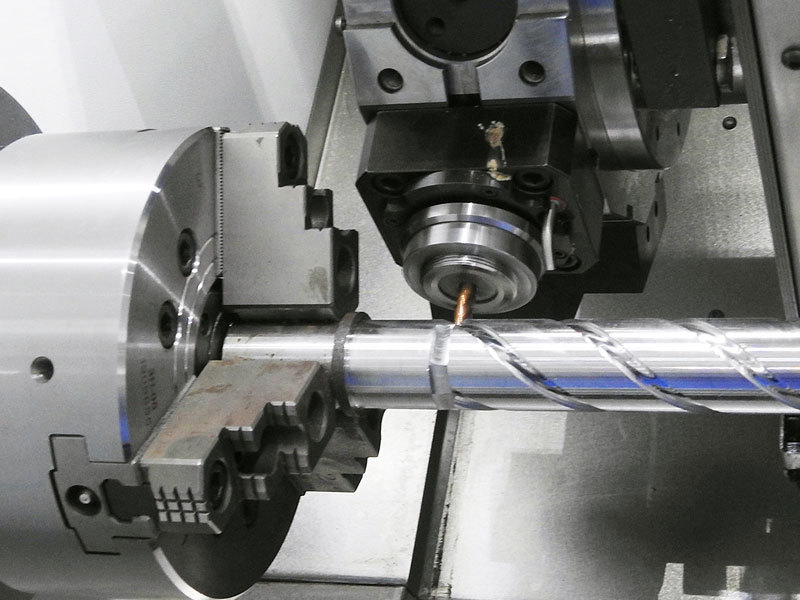

Firstly, we will study how to improve the accuracy of CNC lathe machining from the perspective of mechanical adjustment. In terms of machine tool adjustment, it mainly includes these parts, such as spindle, bed, and inserts, in order to make the lathe meet the requirements and improve the accuracy of CNC lathe machining. Regular monitoring should also be carried out during the working process, and the shortcomings in the lathe should be continuously optimized in order to adjust the production of better products in a timely manner. This is the simplest and most convenient way to improve the machining accuracy of CNC lathes. This adjustment method does not require good skills, but requires employees to check and adjust from time to time.

Secondly, improvements have been made in the field of electromechanical integration. To improve the machining accuracy of parts, improvements are mainly made in the areas of reverse deviation, positioning accuracy, and repetitive positioning accuracy. In terms of reverse deviation, when the deviation is too large, we need to first correct it mechanically and manually, and then further optimize it professionally when the error is within a certain range. When adjusting the positioning accuracy, the error is continuously optimized through the degree of the microscope. The electromechanical joint debugging method optimized in these aspects is the most efficient among these adjustment methods. Although it may be cumbersome, the effect is quite good.

Thirdly, this is achieved through electrical adjustments, which mainly include two aspects. One is the adjustment of machine parameters, and in this angle, there are two aspects that affect machining accuracy: system gain and positioning dead zone. In terms of system gain, we need to pay attention to the mechanical damping and rotational inertia of the lathe, which all affect the machining accuracy of the lathe. Another way is to minimize the dead zone of positioning as much as possible, which can also improve the accuracy of lathe operation. These two aspects complement each other and need to be adjusted simultaneously. On the other hand, adjustments can be made through the application of some systems. With the continuous improvement of automation, CNC lathes use automation to remotely control during operation. Therefore, we need to enter a series of monitoring programs during remote control, so there is no need for excessive manual intervention. This can be more effectively supervised and controlled through programs, which can improve the accuracy of lathe machining.

PREVIOUS:

Contact Us

E-mail :

fanminga@qijijixie.com

Phone/WhatsApp:

+8613703194661,+8618732920203

Address:

Fuyang High tech Economic Development Zone, Xingtai City, Hebei Province, China.